Valmont® U-BEAM™ Complete Bridge Solution

The First Galvanized Cold Formed Steel Tub Girder Bridge Solution

Whiteside County, IL Bridge Replacement

Valmont® U-BEAM Complete Bridge Solution: Hit play, and learn about the composite 8” Precast Concrete Deck on 18” Valmont® U-BEAM TM Tub Girders that were used for the Howland Creek Bridge Replacement with Whiteside County Engineer, Russ Renner, PE, SE.

Cast-in-Place Deck Option

Hit play, and learn about Valmont® Bridge U-BEAM™ solutions remove the obstacles to construction so that building new or replacing existing bridges is accomplished faster. These innovative bridge solutions outlast traditionally-built bridges, requiring less maintenance, lowering costs, and improving safety.

Meet the Team

Repairing our nation’s bridge inventory with longer life virtually maintenance-free bridges.

The Valmont® U-BEAM™ Complete Bridge Solution is the ideal solution to your long-term planning needs with its projected service life of 100 years. Increased efficiency during the manufacturing process ensures your bridge can be produced quickly and shipped on time. Once delivered, bridges can be installed in just one day, which reduces construction shutdowns and lowers your cost.

Watch Now

Galvanized Steel Tub Girders for Bridges up to 100’ Per Span

100-year service life gives lowest cost of ownership and also reduced road closures, motorist inconvenience and loss of use during construction.

Previous Bridge Projects

Peoria County

Valmont U-BEAM Complete Bridge Solution

The First Galvanized Cold Formed Steel Tub Girder Bridge Solution in Illinois

Champaign County

Valmont U-BEAM Complete Bridge Solution

The First Galvanized Cold Formed Steel Tub Girder Bridge Solution in Illinois

How? Key Components Coming Together.

Why Change? Concrete Box Beam & Performance Deficiencies

The side-by-side box-beam bridge was the bridge of choice for short to medium span bridges due to ease of construction, favorable span-to-depth ratios, aesthetic appeal, and high torsional stiffness.

Major deficiencies of the concrete box beam include:

Reflective Deck Cracking (cracking between the beams that reflects to the deck surface)

Only 35 Year Service Life in Extreme Conditions

Early Deterioration of Joints

Limited Corrosion Protection

Performance problems persist despite design changes over the last 70 years. Specifically, the longitudinal deck cracking reflecting from the shear keys, still persist. Reflective deck cracking is identified as the leading cause for triggering.

AASHTO INNOVATION AWARD

Anchor Bay Drive, a 2020 Prize Bridge Award winner, along Lake St. Clair in Clay, Mich., is a press-brake-formed tub girder bridge.

(Photo Courtesy of TEG Engineering)

HOT DIPPED GALVANIZED STEEL BRIDGE LIFE EXPECTANCY

First Hot-Dipped Galvanized Steel Bridge: The 420’ long Stearns Bayou Bridge was constructed in 1966 over fresh water in Ottawa County, Michigan. It was the first hot-dipped galvanized steel bridge erected in the U.S. and provides a great case study of the durability of galvanized steel. The bridge carries light to medium traffic flow and is treated with road salt in the winter.

KEY ADVANTAGES

LEADTIME

10-12 week Delivery Leadtime

SERVICE LIFE

100-year Service Life

REDUCED ROAD CLOSURE

Reduced road closure duration, reduced traffic delays – quick installation.

BEST RETURN ON INVESTMENT

Best economical optional compared to traditional concrete box beams. More than 2X the projected service life.

LIGHTER WEIGHT

Substantially lighter weight than concrete box beams allows use of smaller installation equipment.

PROVEN PERFORMANCE

Add your pricing strategy. Be sure to include important details like value, length of service, and why it’s unique.

KEY FACTS

Skews up to 45 degrees Meets IDOT Specifications, plans and special provisions available for design reference

Follows AASHTO LRFD for HL-93 loading Compatible with AASHTOware Load Rating Program

Easy to follow and check Mathcad calculations Con-Struct’s Engineers will design a bridge at no charge to meet your parameters

Steel Press-Brake-Formed Tub Girders are a 2021 AASHTO Innovation Focus Technology!

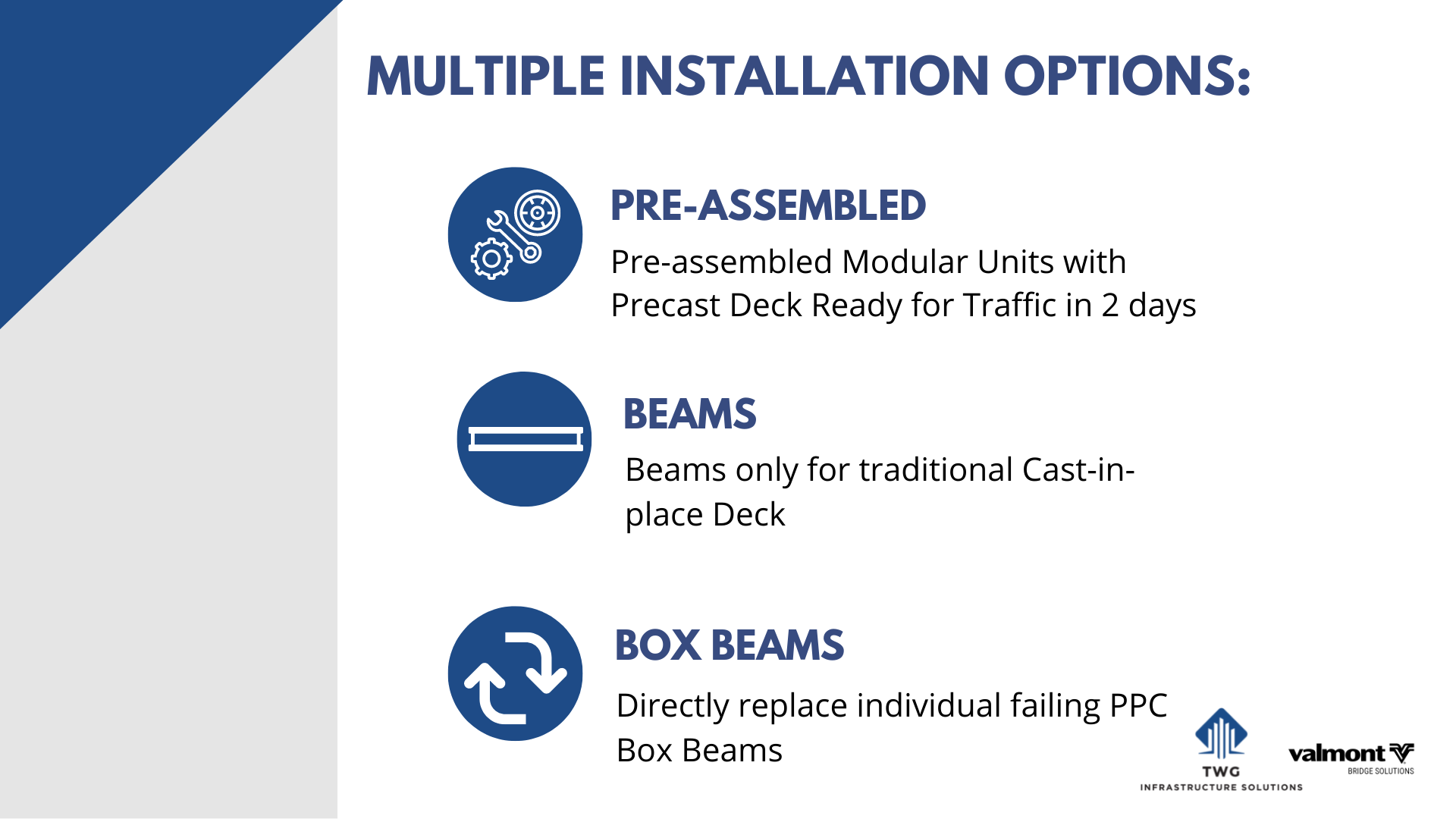

Multiple installation options:

Pre-assembled with precast deck ready for traffic in two days

Tub Girders and precast deck shipped separately for field assembly

Tub girders delivered to site for cast-in-place deck

Wide range of spans available: from 25’ to 100’, with an unlimited number of spans

Long life – projected service life 100 years

Designed per AASHTO section 6.11 Box Section Flexural Members.

Reduced road closure duration, reduced traffic delays – quick installation

Substantially lighter weight than precast concrete box beams

Economical compared to traditional concrete box beams:

More than twice the projected service life

HIGHLIGHTED BRIDGE PROJECTS

Valmont® Bridge Systems Install | Petersburg Road Over Swamp Raisin Creek

Valmont® Bridge Systems | U-Beams™ and Deck Timelapse

Peoria County Looks to Steel for Innovative Bridge Replacement Project

Peoria, Illinois Assistant County Engineer Jeff Gilles thought it was time for a change. Faced with a backlog of short span bridges to replace and limited funding, he was ready to try an innovative modular approach endorsed by Brian Keierleber, P.E., Buchanan County Engineer in neighboring Iowa, who was enthused about a steel press brake tub girder bridge (PBTG) he had installed.